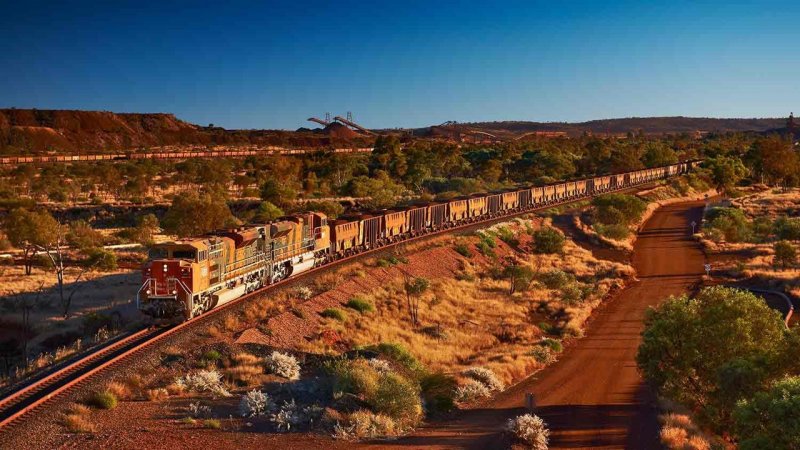

Geographically vast and remote, Rail is a key component of the Resource sector supply chain. Getting the product from mine to port or mine to production safely and efficiently is very much dependent on an optimised rail network.

Within the Rail Applications and Communications network, safety is the number one priority closely followed by the efficient and reliable delivery of critical services to mining operations and the thousands of people under mining companies’ duty of care and public safety.

We understand the role data and technology play in optimising the delivery strategies from pit to port however, rail often becomes an island within the technology landscape and the challenge is to integrate certain components safely and securely into an overall technology standard. Importantly, we also understand the difference between Vital and Non-Vital applications and what to leave to the Signalling and Communications experts. We also know how to act as a conduit between the rail, technology and engineering to ensure the right outcome is achieved.

Challenges We See Right Now

- Wayside systems like various image inspection technologies, temperature monitors (Hot Box/Cold Box detectors), DED, acoustic monitoring and condition monitoring systems are typically installed as separate projects, increasing the non-vital footprint on the Rail Applications and Communications network. Over time, the support burden exceeds team capacity.

- As rail networks expand, the requirements for ongoing data capacity planning, training, and forecasting can’t be overlooked or you risk delays in critical fault resolution caused by a lack of:

- Standardisation

- Monitoring

- Integration

- Team Knowledge

- Manageability

- Lack of visibility of critical infrastructure leading to ad-hoc and uncoordinated support

- Degradation of technology equipment leading to regular equipment failures and an increase in the number of faults

- Increases in outages and the time to repair impacting the safety of rail operations and reducing rolling stock capability and capacity

- Increase in maintenance costs of both technology and rolling stock assets

- Lack of cohesion between engineering, technology and rail teams

How We Can Help

- Methodically map, catalogue and document all devices, applications and systems used with your rail network

- Differentiating between Vital and Non-Vital

- Ensuring the system categorisation is known and agreed with stakeholders

- Determining Backup, High Availability and Disaster Recovery requirements for specific components

- Confirming the existing documented procedures (both org and vendor) are happening

- Develop a customised plan to address any pain points

- Consolidating, standardising and modernising rail technology infrastructure primarily around rolling stock maintenance and asset protection

- Bridging the technology and rail communications team, identifying the right resources and skillsets to enable improvements in suppor

The overall benefits of these activities include:

- Freeing up resources to focus on core maintenance and fault response tasks

- Improvements in the mean time to repair

- A proactive approach to technology asset repair

- A reduction in outages and lowered risk of service disruption

- Better utilisation of specialist skills within teams

- A decrease in the training costs for support resources

Non Vital Rail Network Optimisation

Geographically vast and remote, Rail is a key component of the Resource sector supply chain. Getting the product from mine to port or mine to production safely and efficiently is very much dependent on an optimised rail network.

Interviews from Austmine 2021 Mining Innovation Conference

During Austmine 2021, Keren Jenns, Principal Consultant Technology, Strategy & Transformation and Simon Charewicz, Head of Digital Execution at Denver were interviewed on 7 current issues.

Has Digital Maturity in Resources & Energy Reached a Tipping Point?

Digitisation in the Resources & Energy sectors is maturing from tentative experiment to application at massive scale. Mines and refineries are now striving for digital maturity and realize it is no longer a question of whether they can afford to do something, but rather a question of whether they can afford not to.